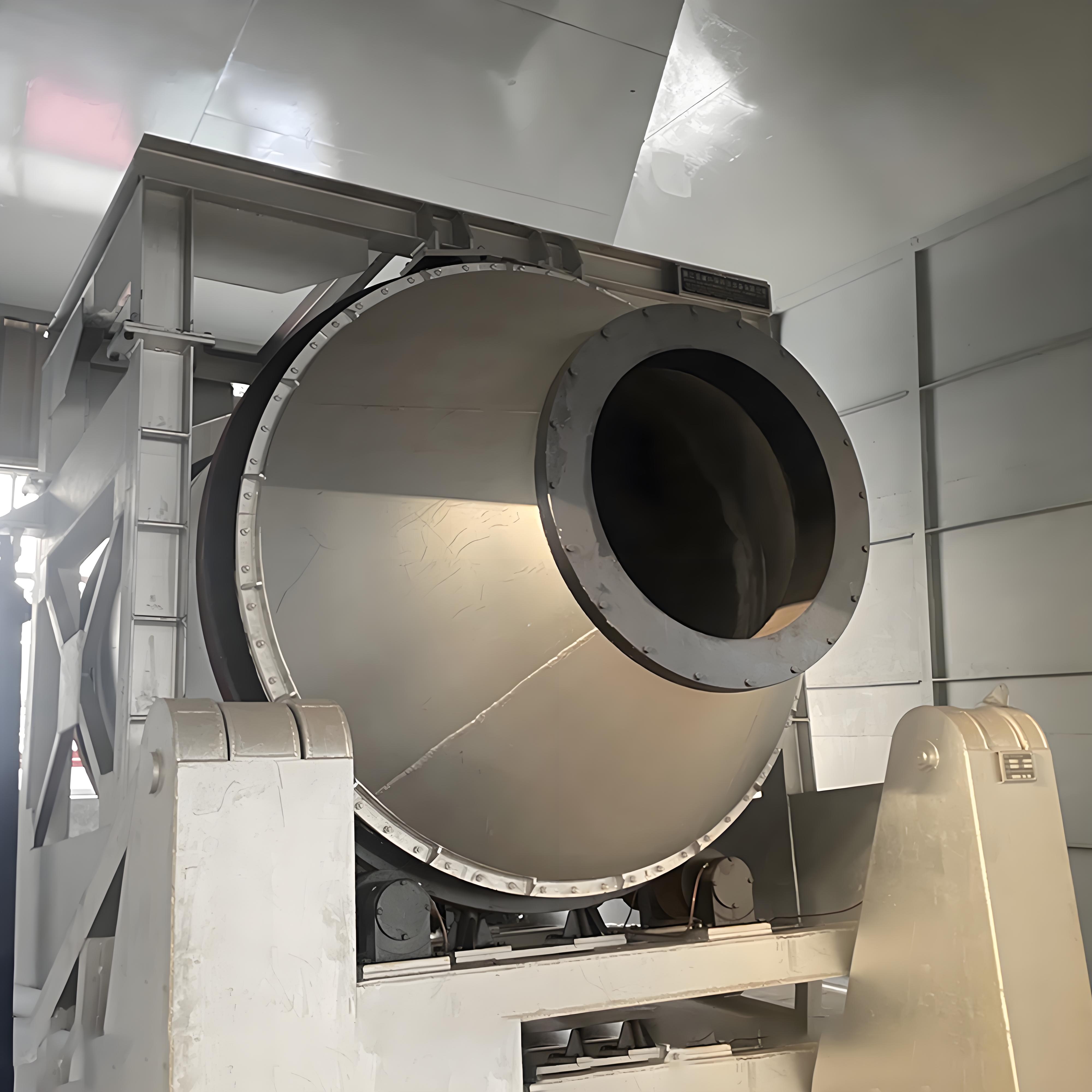

As a rotary furnace manufacturer, we are well aware of the stringent requirements of high-purity antimony smelting on equipment performance and process control. In the rotary furnace pyrometallurgical smelting process, the antimony sulfide concentrate is crushed and screened, and then enters the furnace with a particle size of 100~200mm. The efficient volatilization of antimony sulfide is achieved by precisely controlling the rotary furnace speed (0.5~1.5rpm), the tilt angle (2°~5°) and the furnace atmosphere (micro-oxidation environment, oxygen concentration 5%~8%). The temperature in the furnace is strictly controlled at 900℃~1200℃, so that antimony sulfide is oxidized to form antimony trioxide (Sb?O?) and volatilizes with the flue gas, and is collected by the condensation system to obtain high-purity antimony oxide powder.

The technical difficulties are concentrated on heat balance control and impurity separation. Since antimony is easy to volatilize and oxidize, the traditional process often causes kiln ringing due to local overheating, affecting continuous production. In this regard, we innovatively adopt oxygen-enriched combustion technology, which can strengthen the metallurgical process and reduce energy consumption by precisely adjusting the oxygen concentration. At the same time, we optimized the condenser temperature gradient design and added a multi-stage bag dust removal device to increase the recovery rate of antimony oxide to more than 95%, and the product purity reached 99.99% stably.

In response to the problem of low-concentration SO? emissions, we equipped a dual-alkali desulfurization system to reduce the SO? concentration in the flue gas to below 20mg/m3, which is far below the national emission standard. In addition, the temperature field distribution in the furnace is optimized through AI algorithms, which reduces fuel consumption by 15% and increases the direct recovery rate of metal to 92%.

In the future, we will continue to deepen the intelligent transformation of rotary furnaces and develop modular furnace structures to meet different production capacity requirements. Through the collaborative innovation of process optimization and equipment upgrades, we will help antimony smelting companies achieve green and low-carbon transformation.