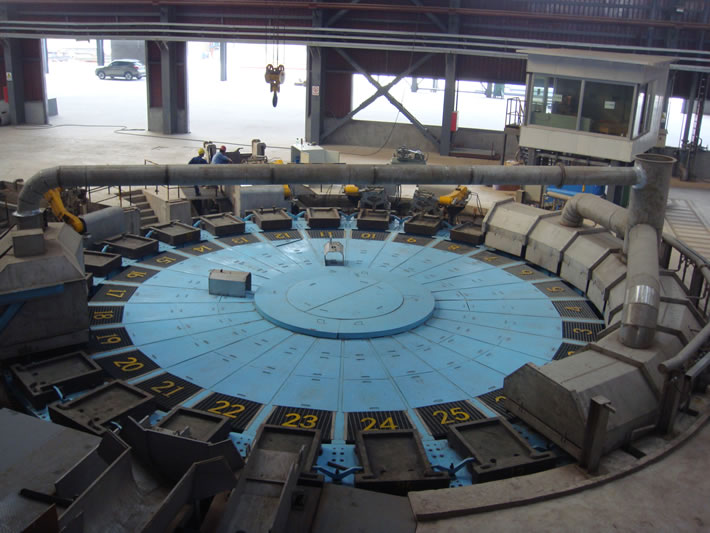

In the process of electrolytic copper production, the key technologies of disc casting machines involve many aspects, such as mechanical structure, temperature control, automation, etc. Today's article mainly analyzes technical aspects such as material selection, casting process parameters, energy saving and environmental protection.

1. Material and high temperature resistant design

1. High temperature resistant alloy parts

Parts such as ladles and molds that contact high temperature copper liquid need to be made of high chromium cast iron (such as Cr28) or heat-resistant steel (such as 310S), and ceramic coatings are sprayed on the surface to extend life.

2. Anti-thermal deformation structure

The equipment frame must have high thermal stability to avoid mechanical deformation caused by long-term high temperature, and water-cooled interlayers or insulation materials are used to protect key components.

2. Optimization of casting process parameters

1. Pouring speed control

Use quantitative ladles or electromagnetic pumps to accurately control the flow of copper liquid. Too fast speed is easy to cause splashing, and too slow speed affects the uniformity of solidification.

2. Pressure and vacuum technology

Some high-end equipment introduces low-pressure or vacuum casting technology to reduce bubble defects and improve the density of anode plates.

3. Energy saving and environmental protection technology

1. Waste heat recovery system

Use the waste heat from the cooling process of copper liquid to preheat the mold or generate electricity to reduce energy consumption (can save 10%~15% energy).

2. Dust treatment device

Integrate bag dust removal or wet electrostatic precipitator system to capture SO? and metal dust generated during casting to meet environmental emission standards.

4. Safety protection and fault diagnosis

1. Emergency braking system

Configure redundant sensors and emergency stop buttons to prevent mechanical jamming or copper liquid leakage accidents.

2. Online fault diagnosis

Predict equipment abnormalities (such as bearing wear, motor overload) through vibration analysis, temperature monitoring and other means to reduce unplanned downtime.

5. Maintenance convenience design

1. Modular structure

Molds, ladles and other vulnerable parts adopt quick-disassembly design to shorten maintenance time.

2. Self-cleaning system

Spray release agent on the mold surface or configure automatic slag removal device to reduce the frequency of manual cleaning.

The comprehensive application of the above technologies ensures the efficient, stable and reliable operation of the disc casting machine, providing a strong guarantee for the production of electrolytic copper.