Work principle:

The copper water flows from the copper outlet of the anode furnace to the tundish through the chute. The tundish is equivalent to the storage of copper water.

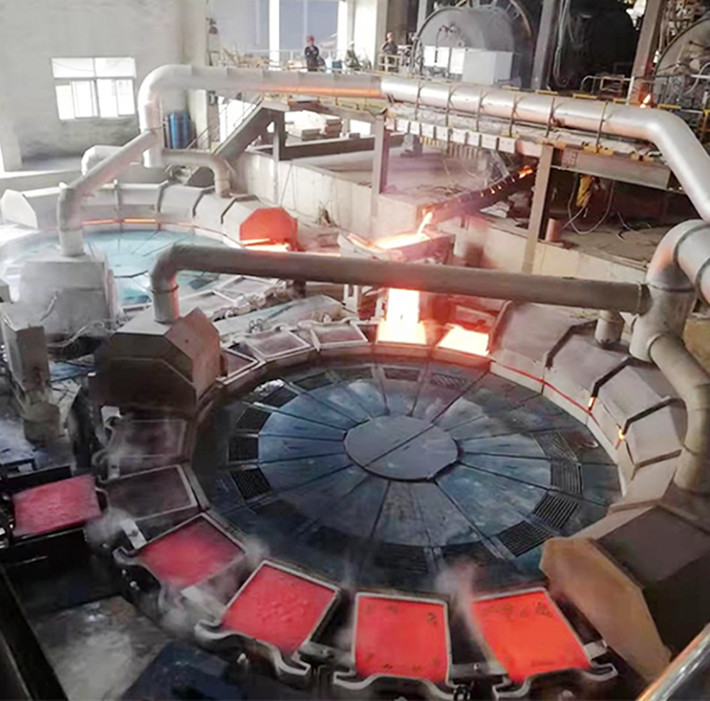

It is a storage device that alternately pours copper water into the casting ladles on both sides. The casting ladles are placed on an electronic scale. We collectively call it a quantitative casting device. The weight of the cast anode plate is controlled by it; during the entire casting process, the disc is in operation. During the alternation between and pause, when the disk is stationary, the quantitative casting equipment

Pour copper water into the casting mold. After casting, the disc rotates two mold positions to cast the next anode plate. After the anode plate is cooled by spraying, the anode plate is loosened from the pre-elevating device. In order to balance the pre-elevating device against the disc Applying upward force, a mold locking mechanism is set above the copper mold at the pre-lifted position; the loosened qualified anode plates are taken away by the extraction machine, and the unqualified anode plates are taken away by the waste anode crane; the extraction machine is taken away The anode plates are placed in the water tank to cool again and are automatically arranged into anode stacks, which are finally transported away by a forklift. The empty copper mold is transferred to the mold coating position, and BaSO is sprayed on it by the mold coating system. mixture to prevent the anode plate from "sticking to the mold". By repeating the above process, continuous casting can be achieved.

Structure:

The disc quantitative casting system is mainly composed of six subsystems: quantitative weighing and casting system, disc drive system, extraction machine system, spray and spray system, water tank transmission drive system, stamping mold and waste mold processing device. The double disc casting machine is a casting machine with two independent casting discs. The two discs work independently of each other. Different types of casting molds can be selected according to needs to simultaneously cast copper plates of different specifications. This design The purpose is to maximize the production efficiency of the casting machine.

Feautures:

Electrolytic copper used in industry (containing 99.9%~99.95% copper) is an important industrial-grade raw material and is widely used in the manufacture of special alloys, metal wires, wires, and various high-precision equipment and instruments. The disc quantitative casting system is a system developed to produce high-precision copper plates to meet the needs of electrolytic copper production. This system integrates electricity, hydraulic technology, and pneumatic technology through the application of PLC technology, on-site configuration technology, and on-site automation instruments. It can realize automated production in harsh environments, has the characteristics of high precision and high efficiency, and is easy to operate and save money. Manpower and material resources. The main function of this system is to cast the molten copper in the furnace through a disc quantitative casting machine to cast copper plates with specific specifications and quality to meet the needs of electrolytic smelting production.