The factors that affect the direct recovery rate of anode rotary copper funrace include copper loss during the slag discharge process, copper splash loss during the process of liquid anode copper flowing from the anode furnace to the disc casting machine, waste copper remaining in the casting ladle and the movable chute; the output of waste anode plates during disc casting; and the anode copper consumed by the casting copper mold. Therefore, to improve the direct recovery rate of anode copper, the following four aspects must be taken. (1) Reduce the copper content in the refined slag. (2) Reduce the waste copper generated by the loss of liquid copper during disc casting. (3) Reduce the output of waste anode plates (4) Reduce the consumption of casting copper molds.

Reduce the copper content of refined slag during slag discharge: During the refining and slag discharge process, copper metal is discharged with the refined slag in the form of cuprous oxide, and a small amount of elemental copper is also entrained. The refined slag is added to the converter again, causing copper loss, which directly reduces the direct copper recovery rate. Reasons for high copper content in refined slag: The basic principle of oxidative refining of crude copper is that the affinity of most impurities in the copper liquid to oxygen is greater than the affinity of copper to oxygen, and the solubility of most impurity oxides in the copper liquid is very small. When oxygen in air or compressed air passes into the copper liquid, it will first oxidize and remove impurities. However, in the melt, copper accounts for the vast majority, while impurities account for a very small number, so its oxidation mechanism can be considered that copper is oxidized first.

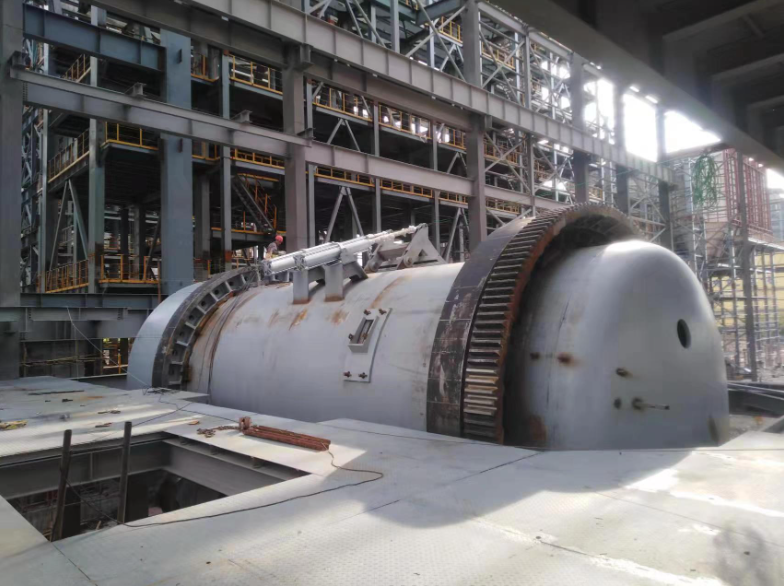

Formulate measures to address the above reasons. (1) Accurately determine the oxidation endpoint and discharge slag in time. (2) The temperature of the oxidation refining process should not be too high, generally between 1130 and 1150°C; reduce the copper content in the slag. (3) If the copper is uneven at the furnace mouth during slag discharge, the elemental copper will be lost with the oxidation slag, so the anode copper furnace mouth must be cleaned before slag discharge. Improve the production of casting ladles and movable chutes to reduce scrap copper losses