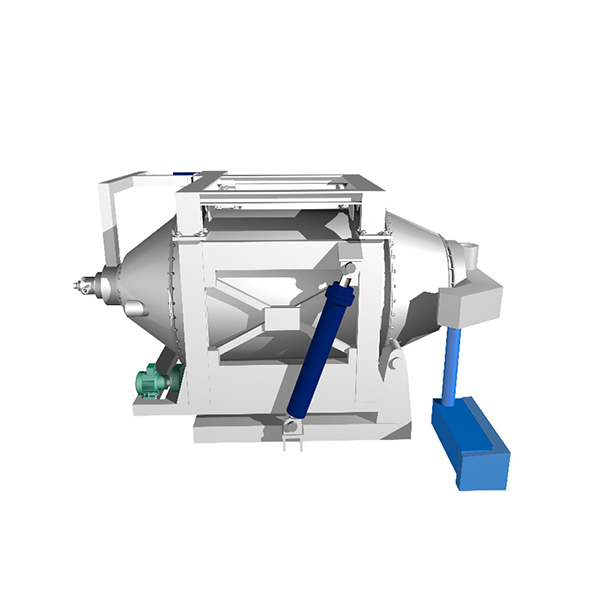

The core of the pretreatment rotary kiln smelting process for low-quality scrap copper lies in utilizing the unique structure and oxidizing atmosphere of the rotary copper smelting furnace to achieve efficient separation of copper from easily oxidized impurities such as iron, zinc, lead, tin, and aluminum, producing black copper. Scrap copper rotary kilns are typically horizontal cylindrical furnaces capable of 360° rotation, equipped with key components such as combustion devices, air ducts, furnace openings, and copper tapping outlets.

During the smelting process, scrap copper is fed into a rotary kiln and heated to high temperatures in an oxidizing atmosphere. At this point, impurities with lower melting points or that are more easily oxidized, such as zinc, lead, and tin, preferentially react with oxygen, forming oxide slag or volatilizing into the flue gas. For example, zinc rapidly oxidizes to zinc oxide at high temperatures and is discharged with the flue gas; lead and tin form corresponding oxides, some of which remain in the slag. Copper, due to its higher melting point and relatively weaker oxidizing properties, mainly remains in a metallic state during the smelting process, gradually melting and accumulating.

The continuous rotation of the rotary kiln ensures thorough mixing of materials within the furnace, accelerating the oxidation reaction and preventing localized overheating or undercooling, thus improving smelting efficiency. By controlling parameters such as furnace temperature, oxidizing atmosphere, and rotation speed, the impurity removal effect can be further optimized, ultimately producing black copper with a high copper content, providing high-quality raw materials for subsequent refining processes.