In the production process of antimony ingots and antimony trioxide, there is a close and important connection between the rotary furnace and the refining furnace.

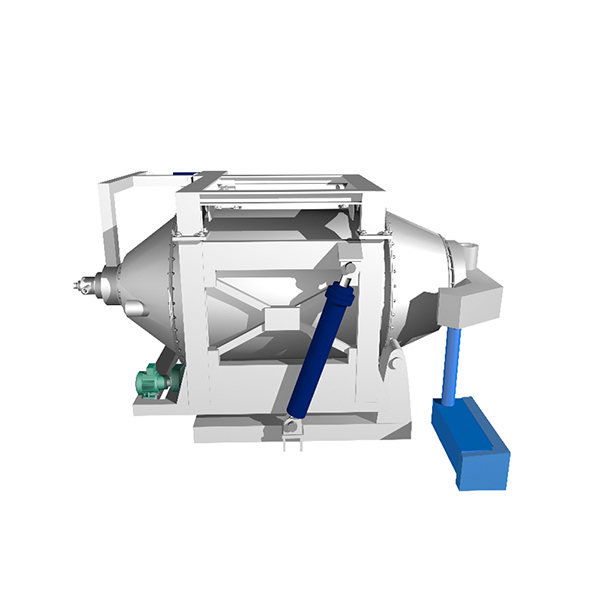

The rotary furnace plays a starting role in the entire production process. It is responsible for the preliminary treatment of the raw materials. After a series of complex reactions and refining, crude antimony metal is produced. This crude antimony metal is the basic raw material for subsequent production, but at this time it still contains a certain amount of impurities and cannot be directly used to produce high-quality antimony products.

The refining furnace is responsible for further purification. The crude antimony metal produced from the rotary furnace will be added to the refining furnace together with a carefully proportioned refining agent. Under the high temperature environment of the refining furnace, through specific chemical reactions and physical separation processes, impurities in the crude antimony metal are effectively removed, and pure antimony liquid is finally obtained.

The subsequent treatment of pure antimony liquid depends on the target product. If antimony ingots are to be produced, the antimony liquid will be introduced into the continuous casting machine. Under the precise control of the continuous casting machine, the antimony liquid gradually cools and solidifies, and finally forms an antimony ingot that meets the standards. If the goal is to produce antimony trioxide, the pure antimony liquid will continue to stay in the refining furnace (also called the oxidation furnace at this time), and an oxidation reaction will occur under specific oxidation conditions to produce antimony trioxide.

It can be seen that the rotary kiln is the source of the entire production process, providing the refining furnace with an indispensable raw material - crude antimony metal; the refining furnace then processes the raw materials in depth on this basis, and finally produces antimony ingots or antimony trioxide according to different production needs. The two are closely coordinated and linked in the production process.