Fire smelting of antimony ingots is a complex and delicate industrial production process, which aims to extract high-purity antimony metal in a rotary furnace and make standard antimony ingots. Each link is closely linked to ensure product quality and environmental protection. The specific process is as follows:

1. Raw material preparation and desulfurization pretreatment

The raw materials need to be carefully prepared and enter the rotary kiln for desulfurization treatment. It can effectively remove most of the sulfur elements through specific temperature and atmosphere control to prevent the impact on subsequent smelting and pollution of the environment. After treatment, desulfurized antimony ore powder is obtained.

2. High-temperature reduction smelting of crude antimony

The desulfurized antimony ore powder is sent to the rotary furnace, and the temperature, atmosphere and other parameters are precisely controlled. It reacts with the reducing agent to produce crude antimony metal. The conditions must be strictly controlled to ensure the output quality. The characteristics of the rotary furnace are conducive to large-scale stable production.

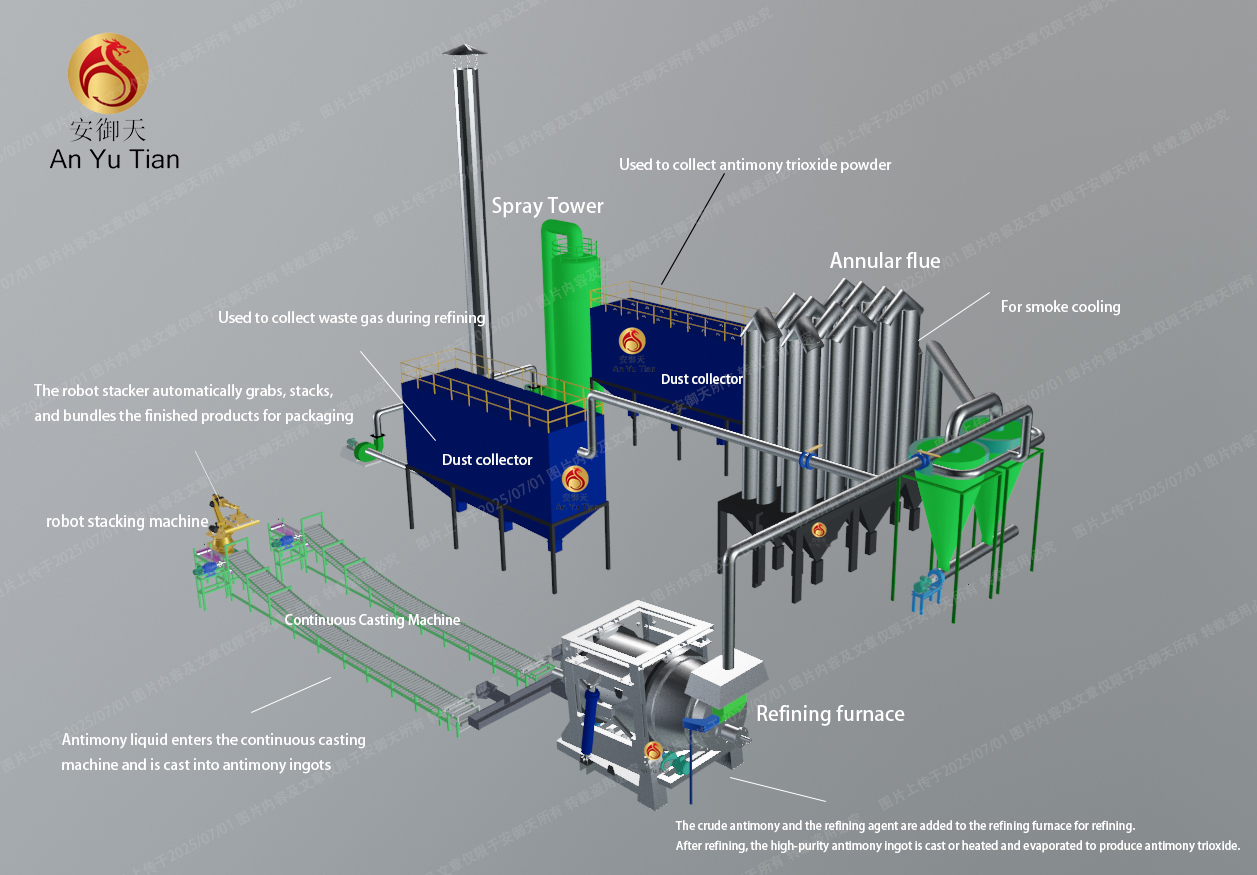

3. Flue gas treatment and resource recovery

The high-temperature flue gas is first cooled in the annular flue, and then enters the dust collector to intercept particulate matter and recover antimony trioxide to improve resource utilization. Finally, it enters the desulfurization tower to complete desulfurization purification to ensure that the emission meets the standard.

4. Refining and purification of crude antimony

Crude antimony and refining agent are added to the refining furnace. The refining agent reacts with impurities at high temperature. The impurities are separated by controlling the parameters to obtain pure antimony liquid. This process requires precise control and rich experience.

5. Continuous casting and finished product packaging

Pure antimony liquid enters the continuous casting machine and is cast into hot antimony ingots. The manipulator stacking machine grabs, stacks, and bundles them to complete the finished product packaging.

This process is closely linked. By optimizing parameters, improving the performance of equipment such as rotary furnaces, and strengthening management, efficient, high-quality, and environmentally friendly production can be achieved to support the development of related industries.