In the field of antimony metallurgy, a single process route often faces the problem of purity bottleneck or poor adaptability of raw materials. However, the creative combination of pyrometallurgy (rotary furnace) and electrolytic refining technology has developed into a key advanced path for producing high-purity antimony trioxide (Sb2O3), especially for dealing with complex antimony ore resources. This process cleverly combines the essence of pyrometallurgy and electrolysis, taking advantage of their strengths and avoiding their weaknesses, and showing significant technical and economic advantages.

1. Low-temperature and efficient desulfurization

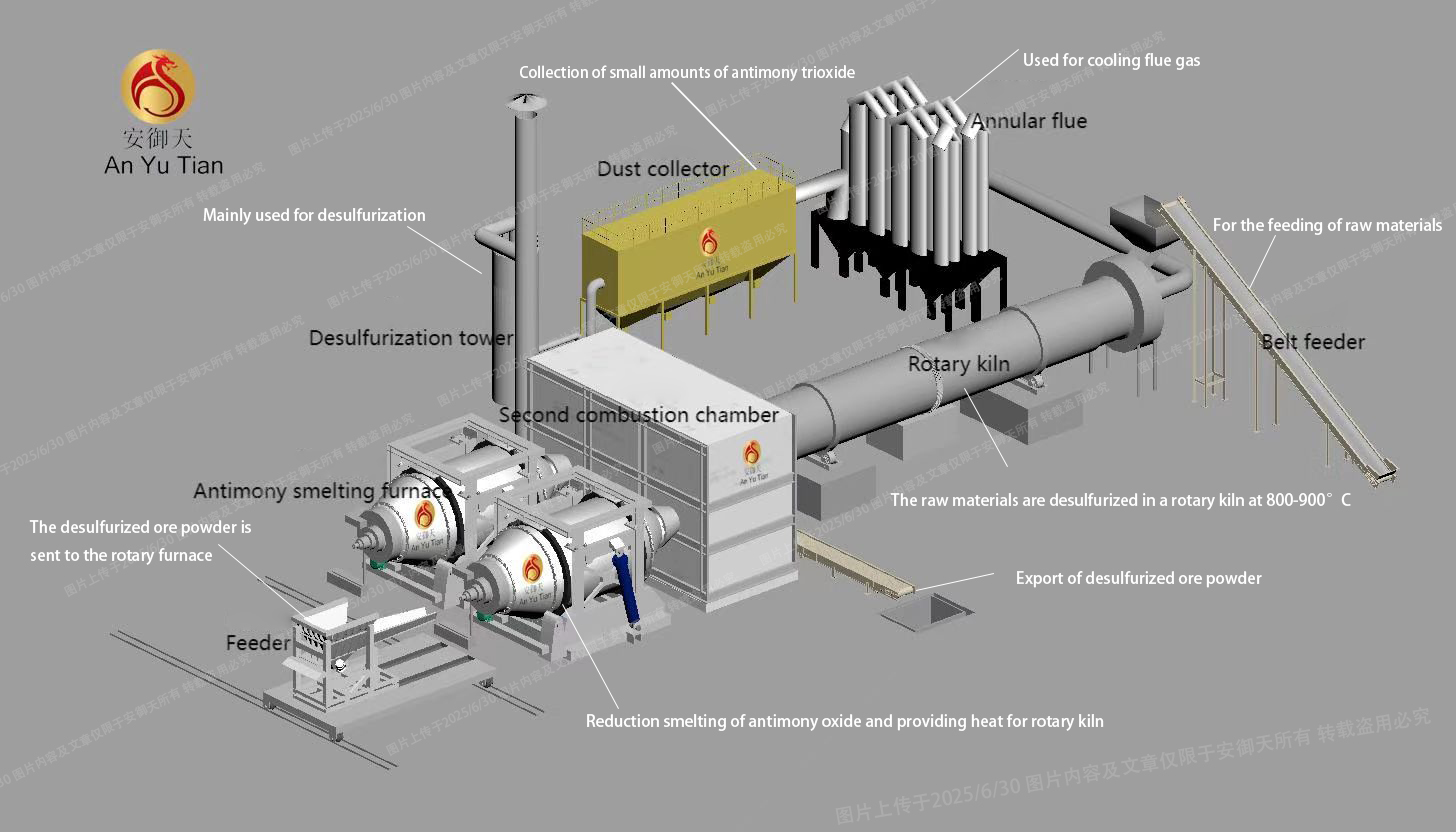

Traditional pyrometallurgy needs to remove sulfur from ore at a high temperature of more than 1200°C, which not only consumes a lot of energy but also causes a large amount of antimony volatilization and high-concentration SO2 flue gas. The use of rotary furnace pyrometallurgy can accurately control the temperature and reducing atmosphere in the furnace. It can efficiently realize the oxidation volatilization or reduction smelting of antimony ore under relatively "low temperature" (800-900°C) conditions, significantly reducing fuel consumption and improving the direct recovery rate of metal.

2. Efficient and continuous production

The traditional pyrometallurgical process is mostly intermittent operation with limited efficiency, while the rotary furnace can continuously process antimony ore and produce crude antimony. The electrolytic refining process can also run uninterruptedly. The entire process from ore to the final product Sb2O3 forms an efficient and smooth continuous operation chain, which greatly improves the equipment utilization rate and overall production capacity.

3. Environmental protection and economy

In terms of environmental protection and economy, compared with hydrometallurgy, pyrometallurgy has significant advantages. It produces less wastewater and can effectively control SO2 emissions through the flue gas purification system. There is no waste gas emission during the electrolytic refining process, and the amount of solid waste generated is relatively low. At the same time, the energy consumption of pyrometallurgy is relatively low, and the equipment investment is also relatively small. Although the energy consumption of electrolytic refining is high, its high added value of products can offset part of the cost.

In summary, the powerful combination of pyrometallurgy (rotary furnace) and electrolytic refining has successfully built an efficient, green and advanced process production line for the production of high-purity antimony trioxide. It not only improves product quality, but also reduces energy consumption and environmental protection costs, injecting strong impetus into the sustainable development of the antimony smelting industry.