The copper refining plant is a complete industrial system designed to extract copper with a purity of more than 99.99% from copper ore or crude copper. The system covers pyrometallurgy, electrolytic refining and supporting processes. The following are its main components and process flows.

In the copper refining process, pyrometallurgy (rough refining) is carried out first. The raw materials are mainly copper concentrate or recycled copper containing 20-30% copper. The copper concentrate is smelted into matte (Cu-Fe-S mixture) by a smelting furnace (such as a flash furnace, reverberatory furnace, etc.). Subsequently, air or oxygen-enriched air is blown into a converter (PS converter) to oxidize the matte into crude copper containing 98-99% copper. The crude copper is further refined in an anode furnace (such as a rotary anode furnace) and cast into anode plates with a thickness of about 40-50mm.

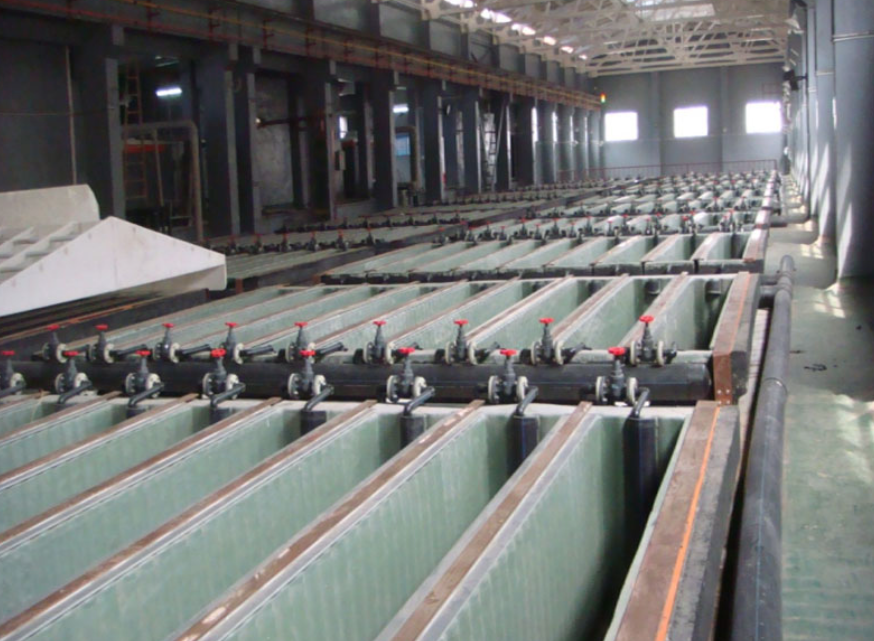

The next stage is electrolytic refining. The anode plate and the pure copper cathode plate are immersed in the copper sulfate electrolyte together. After the direct current is passed, the anode copper dissolves and the pure copper is precipitated at the cathode, with a purity of more than 99.99%. In this process, precious metals such as gold, silver, and platinum and rare elements such as selenium and tellurium can also be recovered as by-products.

The auxiliary system includes waste gas treatment (dust removal, desulfurization), waste slag recovery, and waste heat utilization to ensure the environmental protection and energy saving of the production process.

In terms of the main equipment composition, pyrometallurgical equipment includes smelting furnaces, converters, anode furnaces, and casting machines; electrolytic refining equipment includes electrolytic cells, plate processing equipment, and electrolyte circulation systems; environmental protection and energy-saving equipment covers waste gas treatment, waste slag treatment, and waste heat recovery equipment; in addition, there are automated control systems such as DCS and PLC for process monitoring and parameter control.

When selecting equipment, factors such as production capacity requirements, raw material characteristics, energy consumption and environmental protection, and investment costs need to be considered. At the same time, attention should be paid to process matching, selection of reliable technology suppliers, and environmental compliance. In the future, the development trend of copper refining equipment will focus on green smelting, intelligence and comprehensive resource utilization. If you need more detailed equipment parameters or process flow design, you can leave a message according to your specific needs.