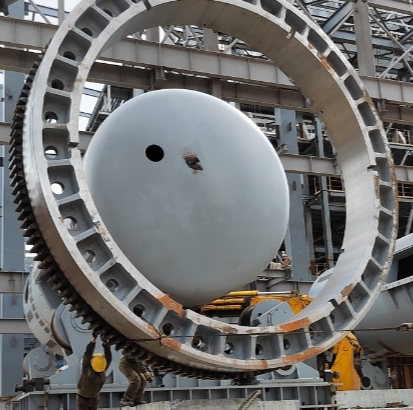

In the past, copper pyrometallurgy was mostly carried out in fixed reverberatory furnaces. This process was gradually replaced by rotary anode furnaces. In today's world, more than 60% of copper produced by pyrometallurgy is refined by rotary anode furnaces. Production practice shows that the domestically produced rotary anode furnace and automatic quantitative casting device have simple structure, stable and reliable production, and advanced technical and economic indicators, especially the success of using heavy oil (or light diesel) as a reducing agent. The rotary anode furnace has the following advantages:

1)The processing capacity is small and medium-sized, which provides reliable experience for the technical transformation of old copper refining plants with "many points and small scale" in terms of scale. 2) The waste heat of the flue gas of the rotary furnace is recycled by waste heat boilers and air preheaters, which not only greatly reduces the unit fuel consumption, but also the steam produced by the waste heat boiler is connected to the steam pipeline of the old plant for comprehensive utilization, so as to reduce the overall energy consumption. 3) The use of heavy oil or light diesel oil for reduction not only reduces the processing cost of anode copper, but also provides the possibility of adopting rotary furnace refining technology in areas lacking natural gas and liquefied petroleum gas. 4) The combustion port and exhaust port of the rotary anode furnace body are at the same rotation center, which further simplifies and compacts the connection between the rotary furnace and the front and rear fixing devices. 5) The automatic control system has strong anti-interference ability and more reliable operation.

The mass fraction of crude copper produced by pyrometallurgical copper smelting is between 98.0% and 99.3%, while electrolytic refining generally requires that the total mass fraction of anode copper impurities be controlled within the range of 0.5 to 1.0%. Therefore, lower-grade crude copper needs to be further refined in a rotary anode furnace to meet the requirements of electrolytic refining.