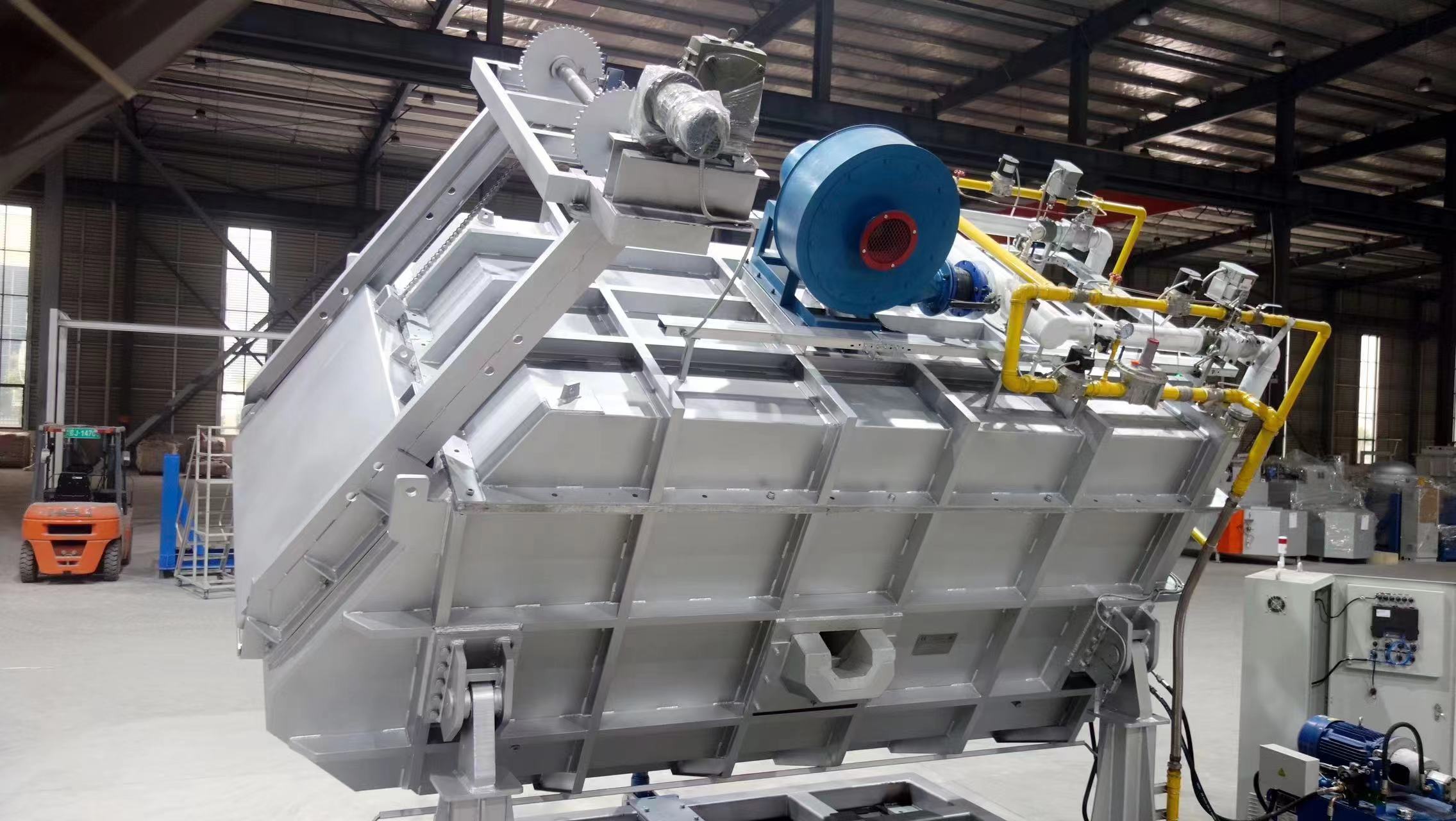

The main research direction of the tilting copper melting furnace is on material selection, structure and manufacturing and installation technology. The specific research plan is to analyze imported materials and find similar or similar materials to replace them; select other materials to replace them based on production practice experience; improve and optimize the structural design of components to better meet the requirements of miscellaneous copper processing and new materials; improve and optimize the manufacturing and installation technology, etc. In order to ensure the molding quality and manufacturing accuracy of the furnace body, the key technology of the tire mold method is used in the manufacturing of the main components. First, effective precision control is carried out from the material cutting process of the components, and the accuracy of the CNC cutting and H-beam assembly equipment is adjusted; the bottom frame, the bottom feeding side, the feeding side wall, the casting side wall and other assemblies are all made in separate transport units.

In order to reduce welding deformation, the control of assembly and welding process should be strengthened. The welding principle is symmetrical, multi-layer, low current, and CO2 gas shielded welding. During production, first assemble as a whole on the mold, split and weld, and correct and shape it into a transport unit structure; after welding is completed and the external dimensions are checked to be qualified, the parts are hoisted on the mold for assembly and adjustment, and then pre-tested and assembled to meet the standards, and then marked and anti-corrosion painted; finally, split, bare, and transported to the site for assembly. The self-developed tilting furnace body can completely replace the imported furnace body, which can save a lot of imported spare parts costs.

Because the two layers of thick steel plates at the bottom of the door frame in the charging port area are severely burned, the refractory bricks that lose their fastening during charging are easily broken by the direct mechanical impact of the miscellaneous copper, and because the furnace port temperature changes frequently with the opening and closing of the charging door, the upper bricks of the door frame are also prone to breakage and serious damage, and bricks fall off. The two layers of thick steel plates can be replaced with water-cooled components to improve the cooling effect and avoid high-temperature burning of the lower steel structure of the tilting copper melting furnace.