To stably produce high-purity antimony trioxide, the key lies in the meticulous control of every aspect of the rotary oxidation furnace. As a critical reaction equipment, the design and operation of the rotary furnace directly determine the purity of the final product. Achieving this goal requires a systematic focus on the following four core dimensions:

1. Structural Design

The furnace body design is far from a simple rotating cylinder. To optimize the oxidation process and impurity separation, the length ratio and internal structure of the volatilization and oxidation sections must be scientifically planned to ensure sufficient and uniform oxidation of antimony vapor, while facilitating the targeted separation of low-boiling point impurities. A precise atmosphere control system is crucial for achieving sufficient and gentle oxidation, directly impacting product quality.

2. Material Selection

The lining material in direct contact with the materials must be made of special high-purity, high-density refractory materials or customized alloys.

3. Control Precision

Temperature is the soul of the reaction. The temperature gradient in each section needs to be precisely adjustable. This relies on an advanced temperature control system and a reasonable heating arrangement to ensure the reaction proceeds within the optimal and stable thermodynamic window.

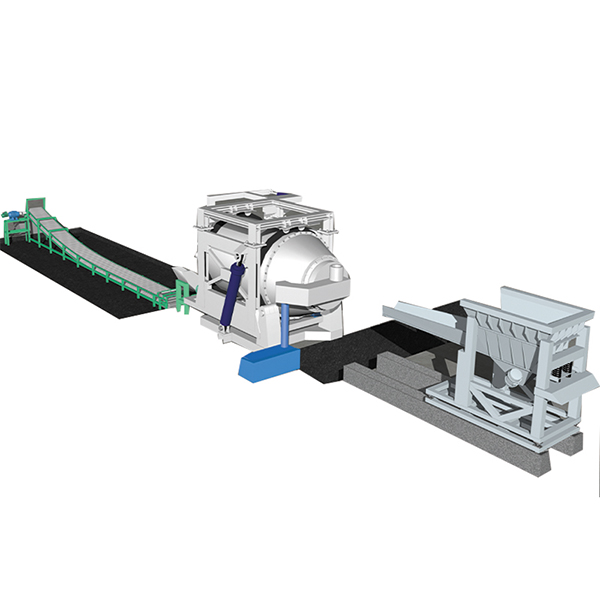

4. System Integration

A high-quality oxidation furnace is not an isolated unit. It must seamlessly integrate with an efficient, sealed flue gas collection and rapid cooling system to quickly capture the product, preventing the re-agglomeration or reverse reaction of fine particles, thus ensuring uniform product particle size distribution and high collection rate.

As a solution provider deeply rooted in the rotary furnace industry, we look forward to providing a solid and reliable equipment foundation for your product upgrades and process excellence with our professional expertise.