In the field of metal processing, converting crude antimony into antimony ingots is a delicate and rigorous process, and each step is related to the quality and performance of the final product. The rotary refining furnace plays a crucial role in this process.

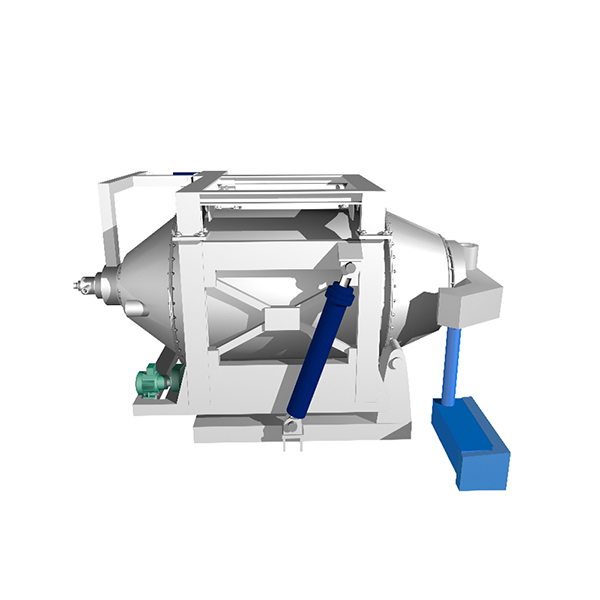

Firstly, refinement is the crucial first step. Crude antimony often contains various impurities, which can seriously affect the purity and subsequent use of antimony. Put crude antimony and carefully proportioned refining agent together into a rotary refining furnace. The unique design of this rotary furnace enables it to uniformly heat the material and allow the crude antimony to fully contact and react with the refining agent through slow rotation. In high-temperature environments, refining agents play a powerful role by reacting chemically with impurities, separating them in the form of slag. After a period of refining in the rotary refining furnace, the crude antimony that originally contained impurities gradually transformed into pure antimony liquid. This process is like a deep purification of antimony, removing impurities that affect its quality.

After obtaining pure antimony solution, it enters the continuous casting stage. Antimony liquid is precisely introduced into the continuous casting machine, where it rapidly cools and solidifies according to a predetermined shape and size, gradually forming into hot antimony ingots. This step requires strict control of temperature and cooling rate to ensure that the internal structure of the antimony ingot is uniform, dense, and has good physical properties.

Finally, the formed hot antimony ingot is automatically grasped by a robotic arm stacking machine. The robotic arm accurately and efficiently stacks the hot antimony ingots neatly, and then performs bundling operations to complete the packaging of the finished product. At this point, crude antimony has successfully transformed into antimony ingots that meet standards and can be widely used in various fields such as electronics, chemical engineering, metallurgy, etc., opening up a new journey of value.